Myself and 2 other teammates entered a 2 day event where our aim was to work as a team to take some E-Waste and create something new.

Myself and 2 other teammates entered a 2 day event where our aim was to work as a team to take some E-Waste and create something new.

Day 1

We decided we wanted to create a CNC plotter as we had seen printers were available for us to disassemble.

Removing the gantry we needed to use:

Removing the gantry we needed to use:

Beginning the process of coding/testing the Arduino + 2 stepper motor setup:

Beginning the process of coding/testing the Arduino + 2 stepper motor setup:

Code for our design linked here

Day 2

Unfortunately the second day of WATTHACK was also the first day of a statewide lockdown and hence was postponed. More to come.

Day 2 V2

After the lockdown all previous designs were scrapped and the event was restarted. We decided to continue on our previous design and managed to source a printer gantry.

At the end of the first day our hardware was coming along well, with 3D printed parts being printed overnight.

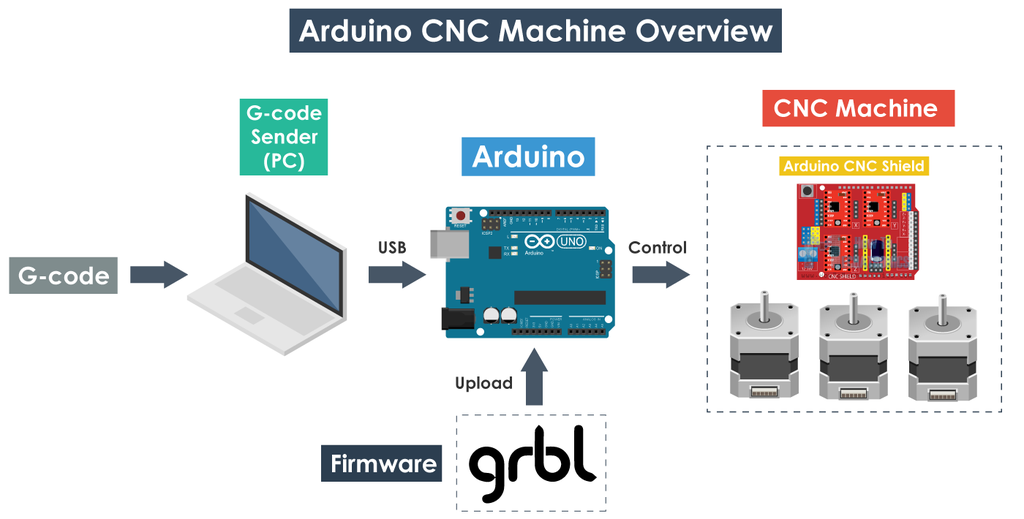

The software still had to be worked out as we were unsure how best to control the interface between the arduino and multiple stepper motors. After a night of searching I found a similar example online that ported gbrl onto the arduino and thus could take gcode instructions.

The only issue was that the code was not set up for our adafruit motorsheild so required a few changes.

The only issue was that the code was not set up for our adafruit motorsheild so required a few changes.

Day 3

The day started with half the team working on assembly and the other half on the code, but as the day went on and the assembly began to slow down the whole team transitioned over to assembly to try and get the structure together.

With 30 minutes left we gave up on producing a pen plotter as the X chassis design was unworkable, instead opting to go for a flag waver, meaning we didn’t have to worry about pen holding.

This change was the perfect spark as it allowed us to throw together all the parts into a working prototype instead of a big collection of parts that should theoretically work.

Given the rush at the end of the day we were unable to setup limit switches which meant that we couldnt develop a system that could follow a preset pattern for fear of breaking our machine. We instead used a CNC Terminal called JCNC to hand in single G-Code steps, although with 5 more minutes we would have been able to set out a very basic pattern (even without limit switches).

Comments