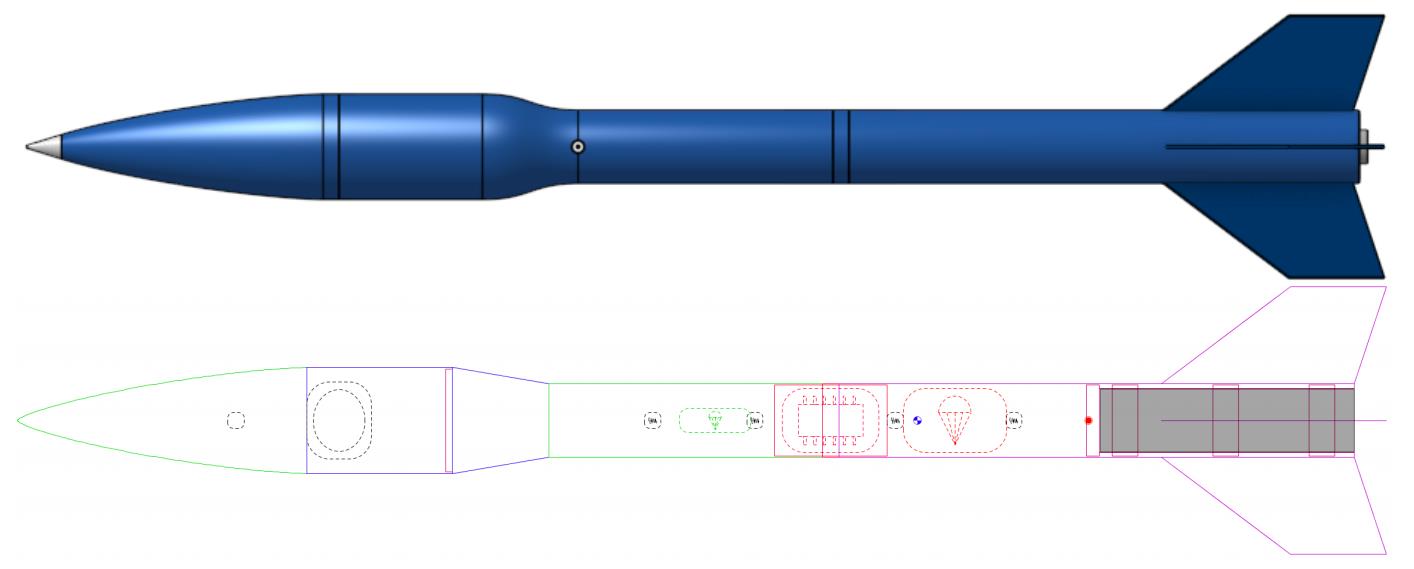

Being the Systems Engineer of Project Phobos for the pioneering Rocketry team at ARES has been a great learning opportunity for myself, requiring me to pick up skills and knowledge that I had never considered important. It has been very exciting to be able to be part of the design and manufacture process, to be able to design something in CAD, make it, then reiterate on that design given all the inefficiencies you find after actually trying to manufacture the thing. Having the opportunity to make mistakes alongside others and learn from one another has also been a great learning experience and has taught me many managerial lessons that I would not have had access to otherwise.

Systems Engineering

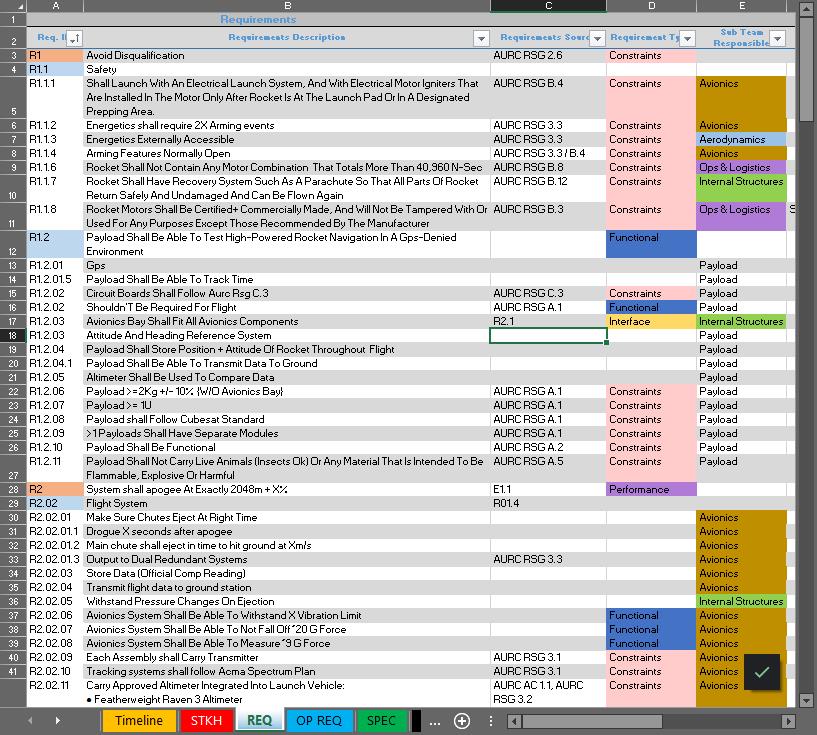

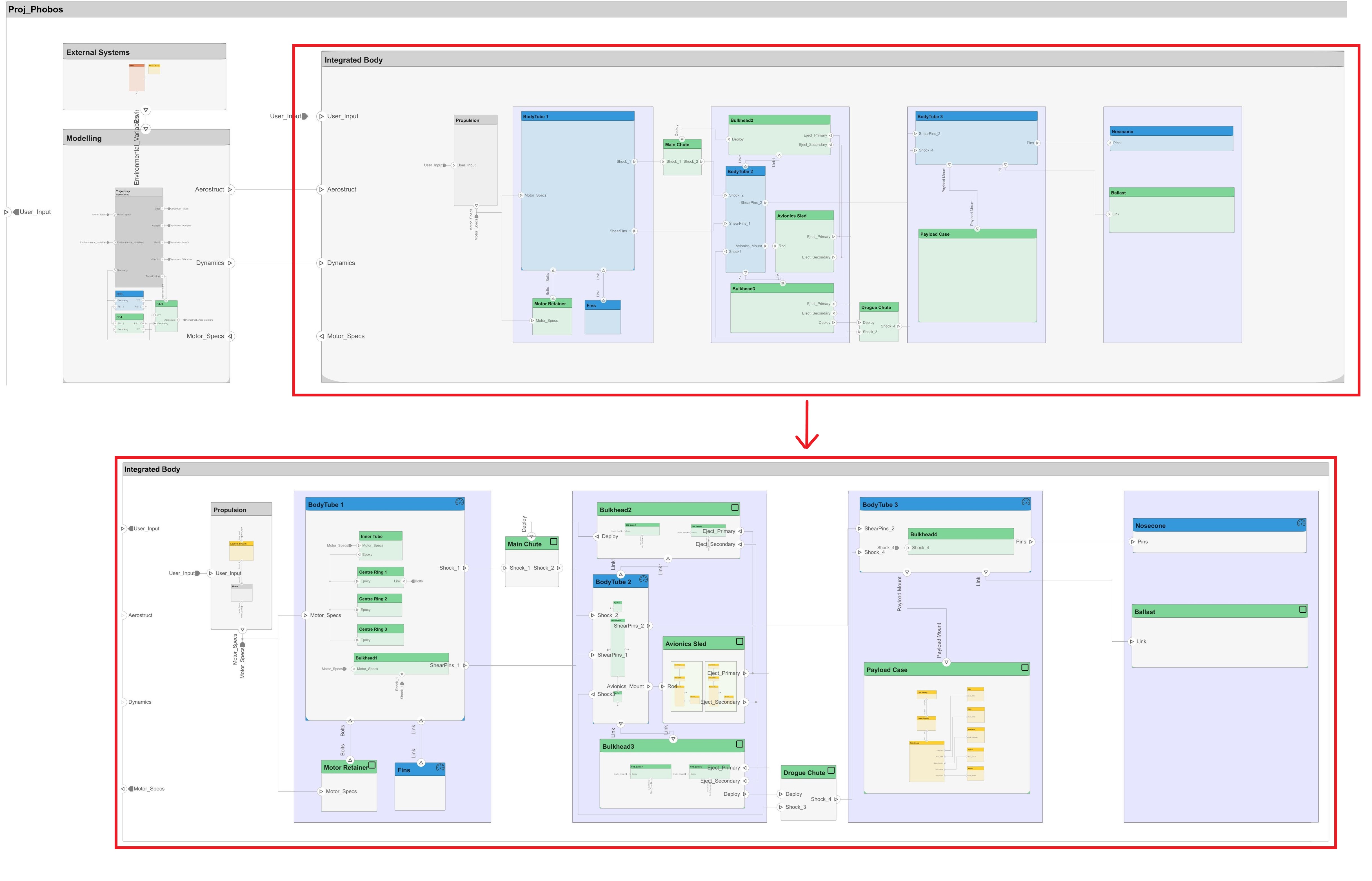

As the systems engineer of the project I have been responsible for ensuring that the subteams of the project are all designing parts that can fit together during the manufacturing process and that fulfil the key requirements decided upon by our management team. I have gone about this in a number of ways:

Requirements Documentation

System Architecture Modelling (Matlab System Composer)

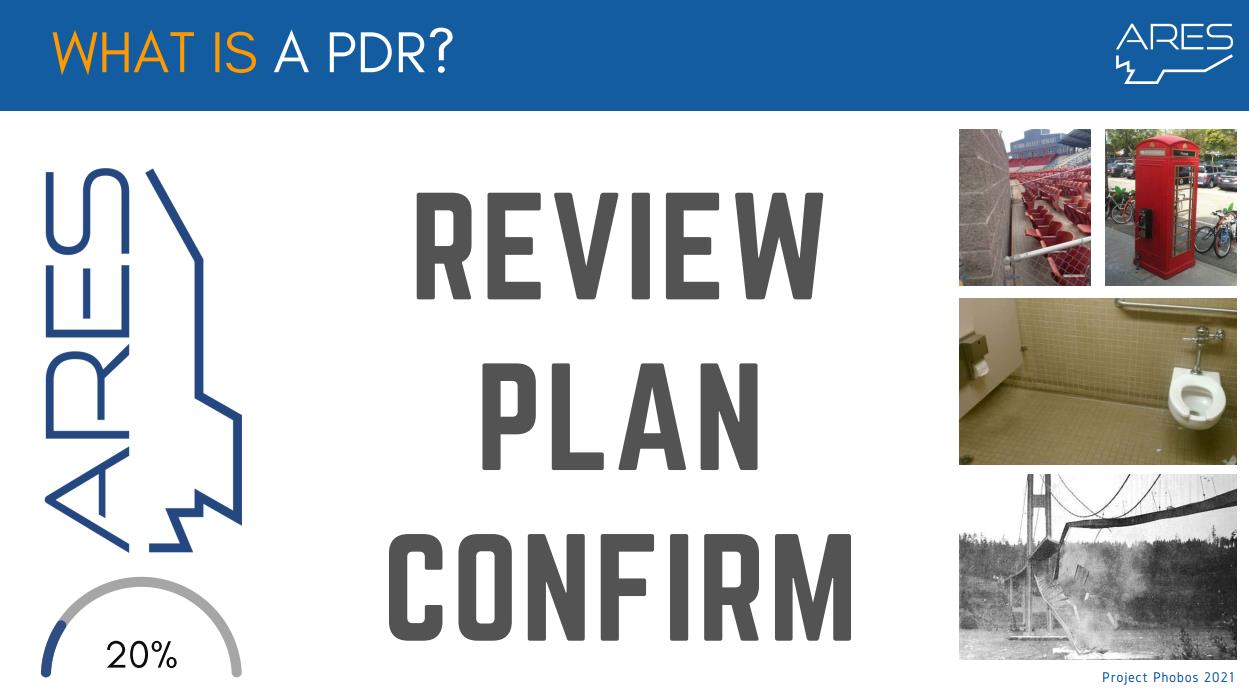

PDR/CDR Implementation

Fibreglass Layup process

As our club is very new and inexperienced we made a lot of mistakes through our layup process which resulted in removal of layups from their mandrels much more difficult than it could have been, although we are well on our way to having a full rocket laid up.

As our club is very new and inexperienced we made a lot of mistakes through our layup process which resulted in removal of layups from their mandrels much more difficult than it could have been, although we are well on our way to having a full rocket laid up.

Body Tubes

Myself and a few other team-members beginning our initial layups for our rocket:

Transition Section

After a lot of struggle we managed to extract the transition although the 3d printed mould was unfortunately destroyed in the process.

Comments