- Static Aerosurfaces

- Heat Shield Development

- Fluids Integration

- Side Projects and Additional Contributions

In my time working as a Development Engineer on the Neutron program I took the opportunity to get as involved in as many different parts of the vehicle as possible, working on everything from heat shields to cryogenic methane seals.

Static Aerosurfaces

My main responsibility was the design and development of the static aerosurfaces of the vehicle. This involved managing interfaces across a wide range of systems. Given that build priorities focused on primary structures (Thrust Module, S1 Tank, Interstage, S2), I often operated independently with minimal resourcing, requiring strong ownership and initiative.

Design and Development

This role required full ownership of the aerosurface subsystems, spanning design, simulation, and manufacturing; demanding tight collaboration with multidisciplinary teams to manage complex system-level interfaces.

Key Achievements:

- Delivered critical vehicle aerodynamic surfaces under aggressive timeline constraints.

- Developed complete flight hardware from concept to production with minimal engineering support.

- Identified and resolved multi-system integration issues independently.

Roles and Responsibilities

Designer

- Led concept development of aerosurfaces from blank-sheet to detailed design.

- Performed systems engineering functions including:

- Requirement capture, derivation, and traceability

- Risk identification and mitigation throughout the lifecycle

- Coordination of reviews from CoDR -> CDR

- Authored interface control documents (ICDs) and participated in system-level configuration control boards.

- Sole owner of Aerosurface CAD in Siemens NX; used Teamcenter PLM for version control, BOM management, and design releases.

- Produced release packages, including drawings and part files, to support internal and external vendors.

- Presented design reviews to senior engineering leadership and program management.

Analyst

- Independently performed FEA structural simulations using NASTRAN (linear statics, buckling, non-linear glue modeling).

- Designed and analyzed Thermal Protection Systems (TPS) using both in-house and proprietary tools.

- Created custom Python-based analysis tools for:

- Thermal and structural modeling

- Data parsing and visualization

- Reusable simulation workflows for future projects

- Implemented version-controlled scripts with

gitfor repeatable, auditable analysis workflows. - Reduced structural design iteration time by automating test-case setup, meshing, and post-processing pipelines.

- Interpolated vehicle-level CFD results across multiple flight trajectories to generate time-varying thermal and pressure environments, which were used to derive structural load cases.

- Contributed to the program’s compartment venting solver, owning 5 of the 8 vehicle compartments and supporting their pressure equalization modeling under ascent, descent, and landing scenarios.

Manufacturing Engineer

- Designed custom tooling and fixtures for:

- Composite layups (plugs, plants, molds)

- Sheet metal forming (formblocks, jigs)

- Large Assemblies

- Interfaced directly with manufacturing technicians to troubleshoot and adapt hardware designs.

- Defined process specifications for hand layup and metal forming.

- Reduced composite part cycle time by streamlining tooling design and integrating DFM best practices.

- Conducted shop-floor support during builds to resolve tooling or fit-up issues in real-time.

Test Engineer

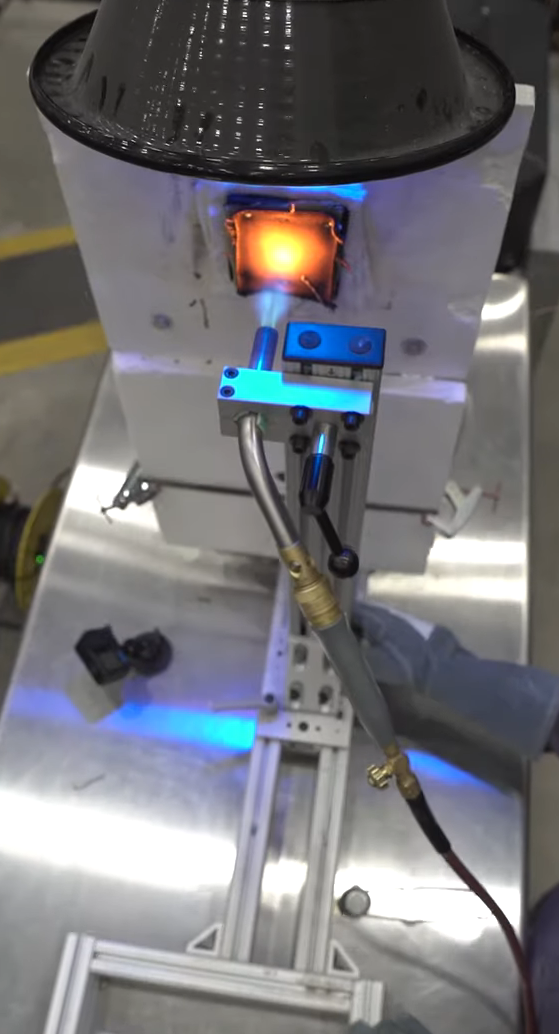

- Supported heat shield component testing, including thermal cycle and propane torch-based exposure tests simulating flight-relevant thermal loads.

- Executed hands-on test operations using torch rigs, high-temperature insulation materials, and custom-built fixtures for representative boundary conditions.

- Installed and calibrated thermocouples on heat shield test articles; supported high-density DAQ systems (NI 9213, NI 9205) with FlexLogger for data acquisition.

- Supported thermal blanket qualification efforts in sensor installation and testbed integration.

- Automated thermal and pressure data analysis using Python.

- Participated in real-time test monitoring, test readiness reviews, and emergency hardware modifications during high-priority test events.

Strakes

Owned the complete development lifecycle of the vehicle strakes, from early concepts to final flight-ready hardware.

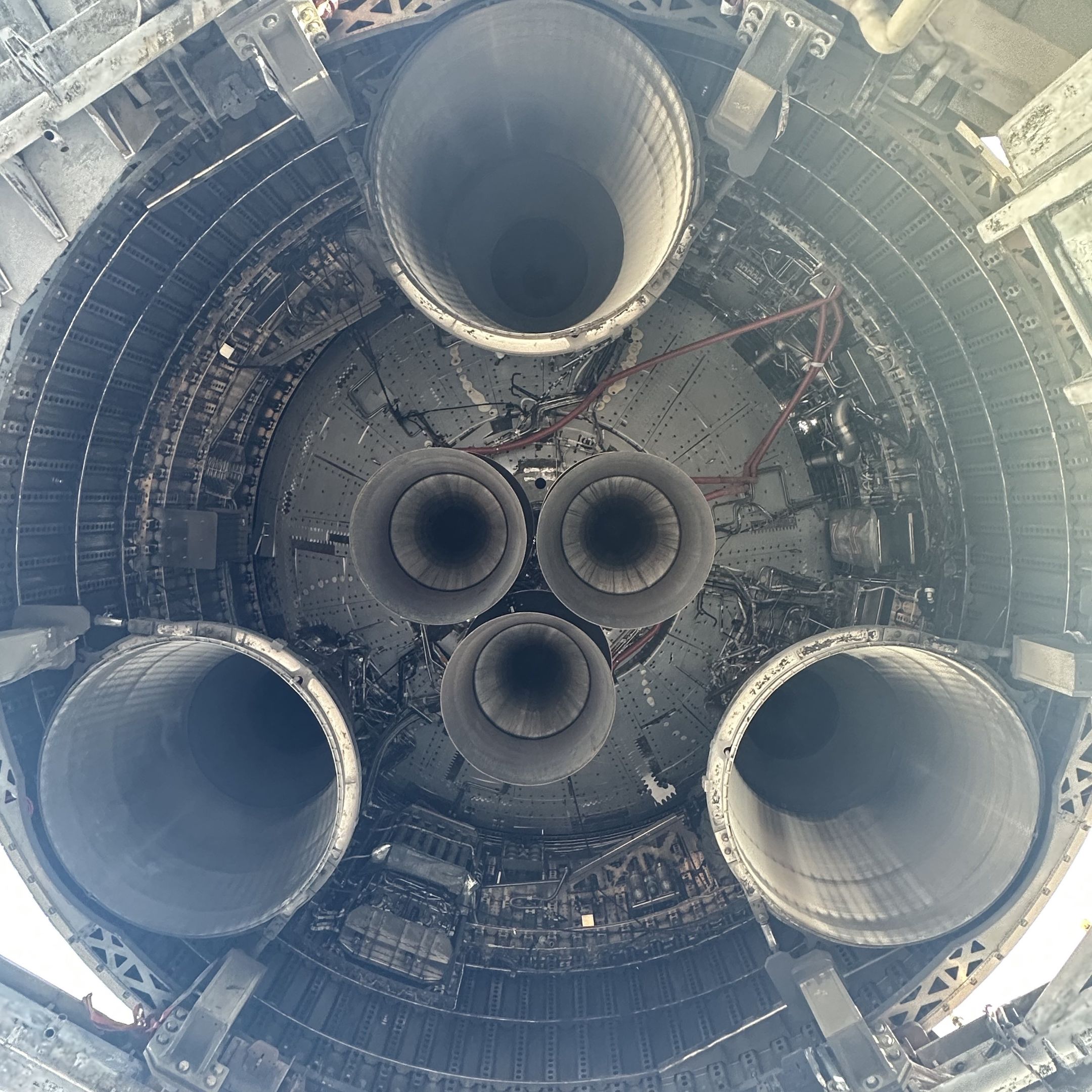

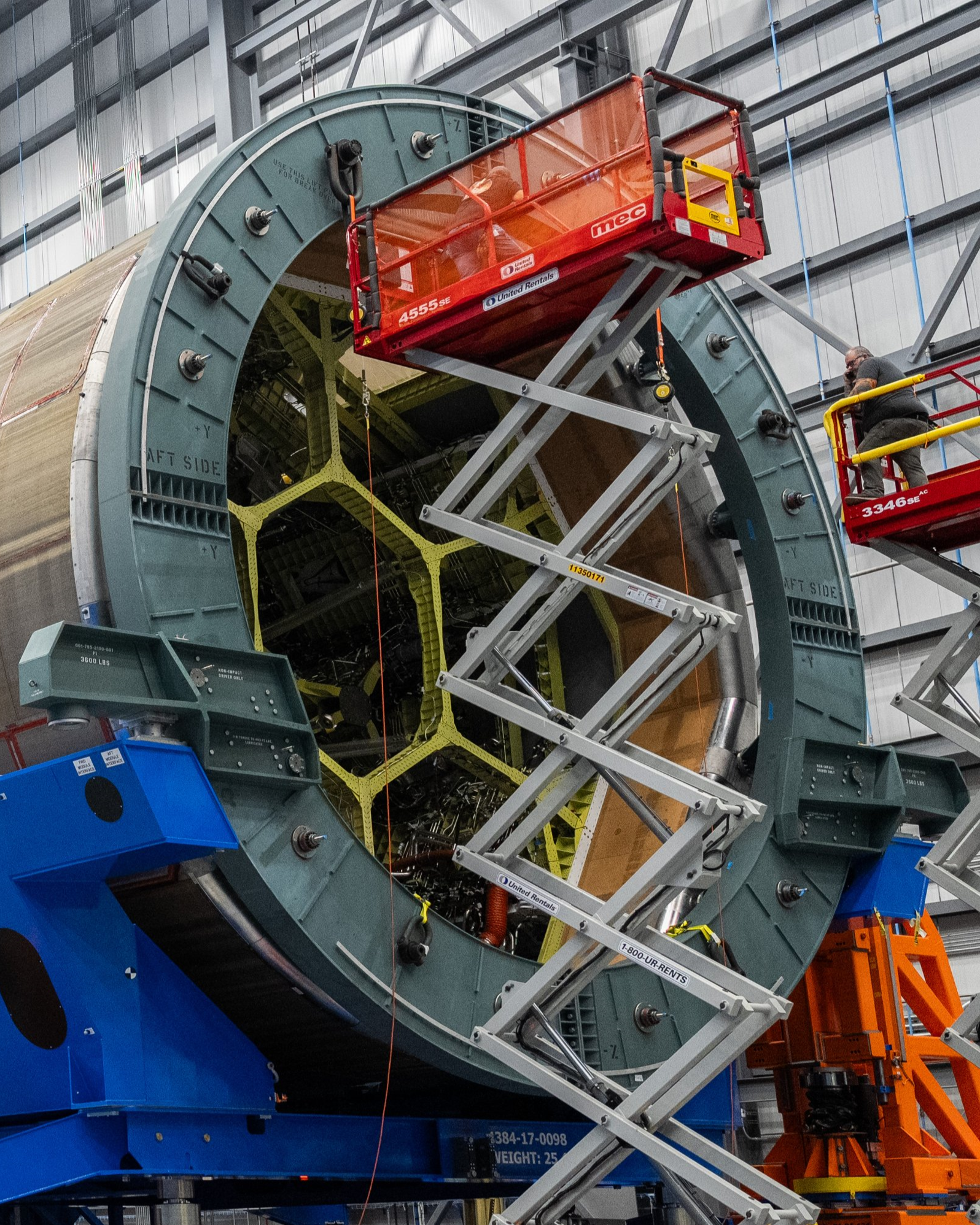

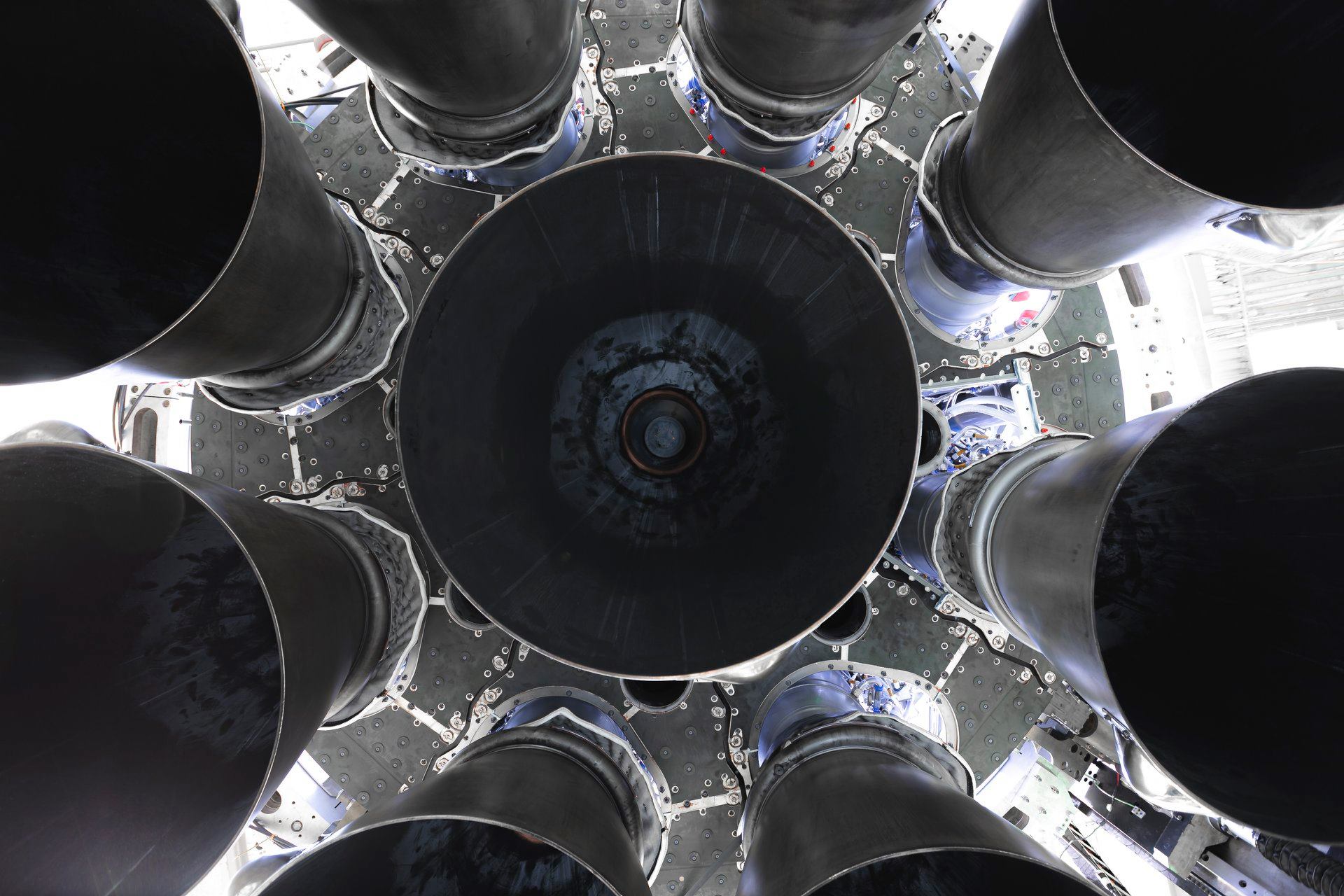

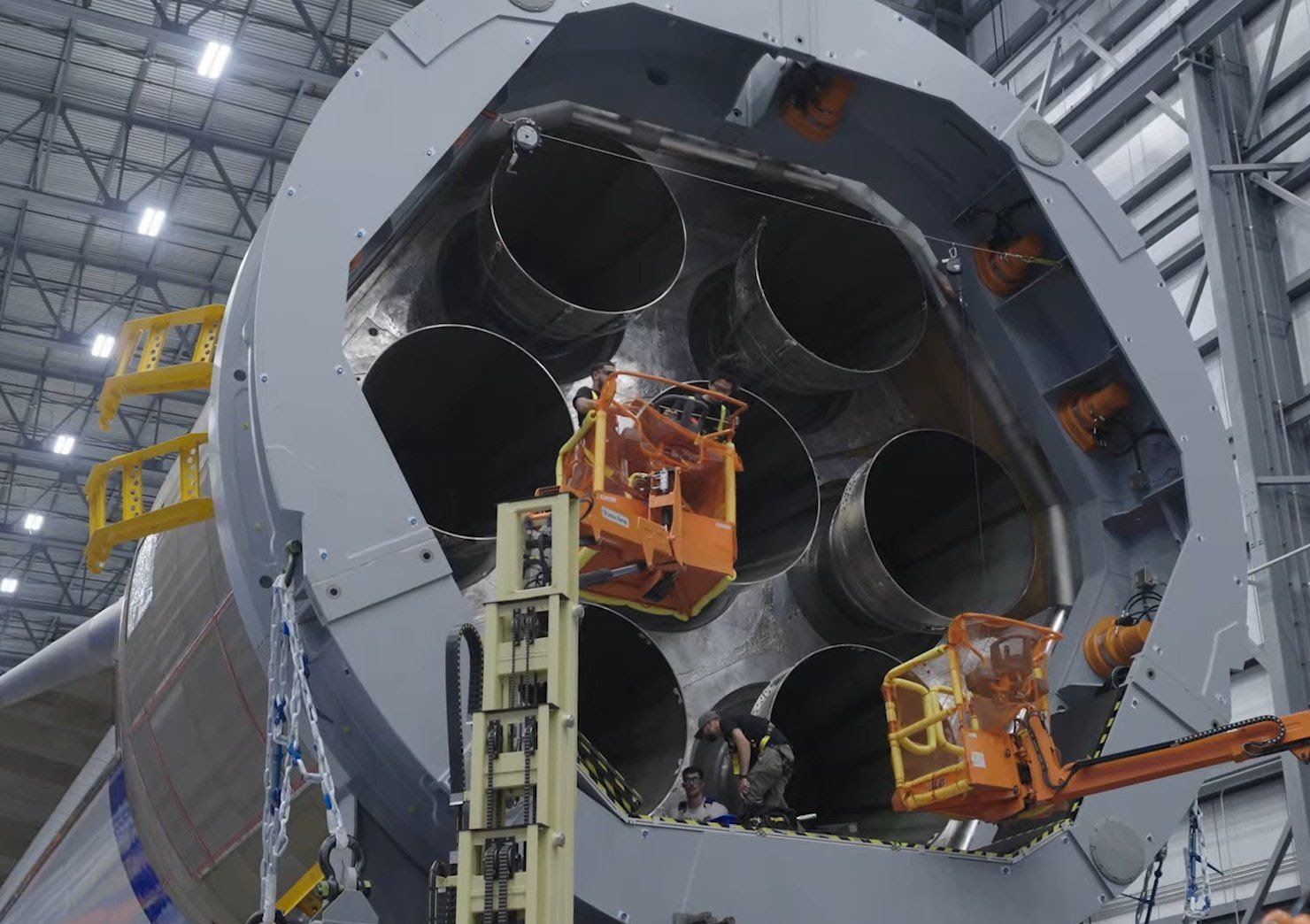

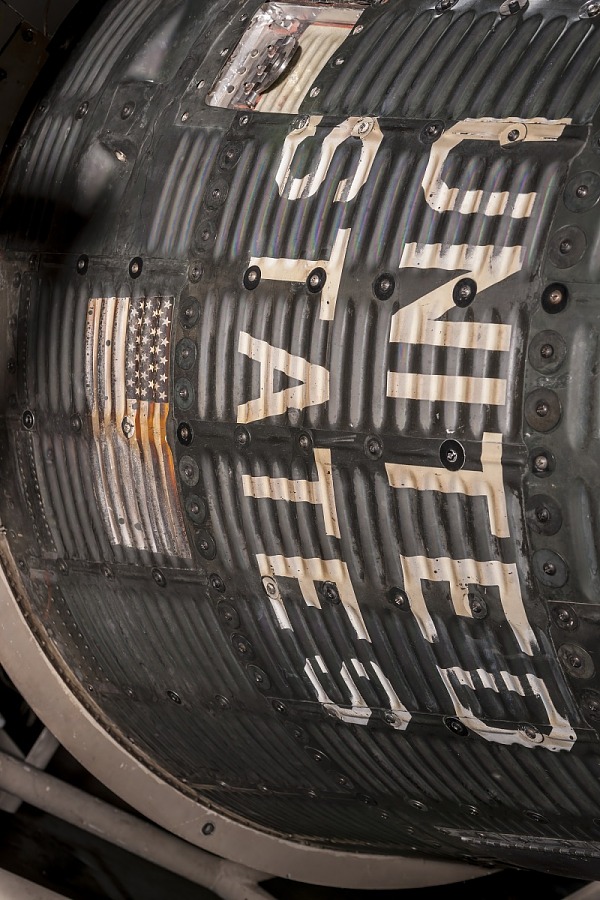

Images below show competititor designs, does not indicate similarity to Neutron designs.

Composite Design

- Utilized Fibersim to define ply layups and optimize structural stacking sequences.

- Engineered sandwich panel architectures for weight and stiffness optimization.

- Developed and manufactured:

- Molds + Plugs + Plants + Bucks

- Managed similar design variants through unique use of NX Part Families.

Analysis

- Ran advanced NASTRAN simulations:

SOL101,103,106, and401for cohesive and bonded composite analysis.

- Focused on composite-specific failure modes and glue line modeling.

- Reduced part weight by over 30% via composite material optimization without compromising performance.

- Achieved first-pass success in design reviews due to thorough simulation and validation.

Aeroshell

Tasked with recovering an aeroshell concept that had failed its PDR, I reworked the entire concept under significant time and interface constraints.

Images below show competititor designs, does not indicate similarity to Neutron designs.

Sheet Metal Design

- Forming techniques:

- Rubber press forming

- Stretching, shrinking, wheeling, flow forming and flaring

- Riveted assembly design and fit-up jig development

- Defined forming specs and tolerances to meet functional and assembly requirements.

Machined Components

- Designed precision parts under tight DFM constraints, with careful consideration for assembly interfaces and stack-ups.

- Applied detailed GD&T and defined critical datums to ensure fit and function across builds.

- Specced materials, surface finishes, and coatings for mechanical and environmental performance.

- Coordinated with internal and external machining vendors on tolerances, cost, and manufacturability.

- Supported first article inspections and resolved NCRs through design updates or concessions.

Analysis

- Used NASTRAN

SOL101,103,106for stress, vibration, and thermal deflection analysis. - Delivered a fully redesigned aeroshell that passed subsequent reviews and transitioned to production.

- Minimized tooling cost by aligning designs with existing press and supplier capabilities.

Heat Shield Development

Supported early-stage development of the reusable heat shield system before the formation of a dedicated TPS team, contributing across design, analysis, and test efforts.

Images below show competititor designs, does not indicate similarity to Neutron designs.

Thermal Analysis

- Contributed to an in-house Python-based thermal solver used by the TPS group.

- Improved runtime performance (~2× speedup).

- Enhanced configuration management for more flexible case setups.

- Used the solver to optimize material selection and thickness distribution across heat shield regions.

Testing & Correlation

- Designed and executed thermal testing of heat shield materials and assemblies, including:

- Propane torch tests

- Environmental chamber cycles

- Realistic thermal load simulations derived from CFD-based environments

- Correlated test results with thermal and structural models to validate the flight performance of the Thermal Protection System (TPS).

- Developed automated post-processing scripts in Python to convert raw sensor data into meaningful performance insights.

- Informed design trade studies and hardware selection by mapping test/model results to vehicle-level thermal environments.

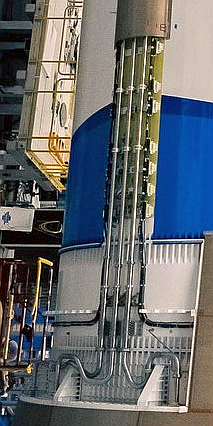

Fluids Integration

Led design of the Stage 1 tank fluids raceway, responsible for fluid routing within a space-constrained launch vehicle environment.

Some images below show competititor designs, does not indicate similarity to Neutron designs.

Key contributions:

- Component design & packaging: Created compact, efficient layouts optimized for performance and manufacturability.

- Routing layout: Engineered fluid line paths to optimise for assembly and avoid system interference.

- Bracket & support structures: Designed mounts to meet vibration, structural, and accessibility constraints for ground and flight ops.

- P&ID improvements: Contributed to the vehicle P&ID Git repository, improving line routing and alignment to improve physical integration.

Enabled safe, reliable fluid delivery critical to Stage 1 propulsion and tank pressurization systems.

CH4 Manifold Design

Owned design of the machined CH4 manifold weldment interfacing with Stage 1 systems:

- System integration: Supported the vent relief valve manifold and autogenous pressurization system through a shared block interface.

- Dual redundant seals: Designed around AS5857-compliant seals at the carbon composite flange for high-integrity pressure containment.

- Welded interfaces: Collaborated with materials/welding teams to ensure structural soundness and manufacturability.

- Tolerancing & geometry: Managed complex port layouts and stack-ups to support fluid sealing and adjacent hardware even under a wide range of thermal loads.

Delivered the manifold from concept through machining and supporting fluid system functionality.

Side Projects and Additional Contributions

CAD Automation Tools

- Developed a custom DXF export tool in NX using NXOpen and Block UI Styler.

- Automated the generation of manufacturing drawings for large sheet metal assemblies.

- Core contributor to internal NX automation scripts.

- Saved ~2 hours per week in drawing generation for large sheet metal assemblies.

- Tool adopted team-wide and contributed to internal process improvements.

Thermal Blanket Testing

- Performed qualification testing of thermal blankets and their controller for curing using NI DAQ tools.

- Verified system response and process accuracy under controlled heating/pressure.

- Utilized:

- NI 9213 for temperature measurement

- NI 9205 for pressure monitoring

S1 Tank Lifting Brackets

- Volunteered for first carbon composite bracket design task.

- Designed lifting brackets used during tank operations and integration.

- Integrated closely with adjacent aerosurface hardware.

MEWP + S1 Fairing Qualification Test

- Supported urgent hardware modifications to enable next-day qualification test execution.

- Assisted in rapid prototyping, fitting, and installation of test brackets.

- EWP certified

Fairing on test stand with internal spyder crane superimposed for clarity. src

Comments