Description

Investigation into the upper loading limits of a cement silo constructed in 1969 which then underwent further strengthening works in 2014. Preliminary capacity assumptions by an external party gave 13730 Tonnes but later this was updated to 17500 Tonnes by another consultant. I was tasked with investigating whether this capacity calculation was over-conservative and was given essentially free reign on this project. By undertaking the below computations I was able to recommend a few minor additions to the structure that subsequently allowed for a load rating of 20100 Tonnes.

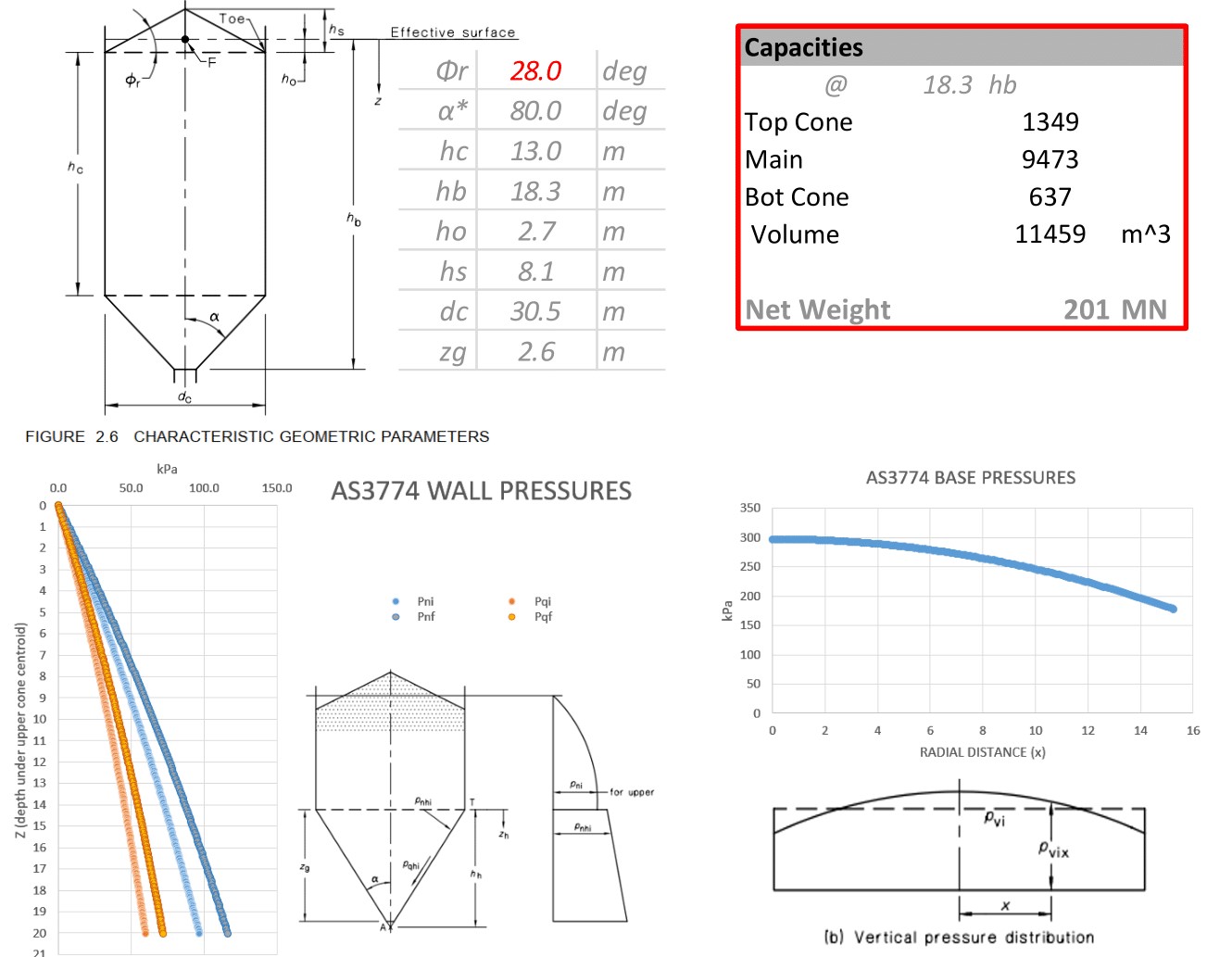

AS3774 Load Calculation

Assuming a maximum capacity of 20100 Tonnes:

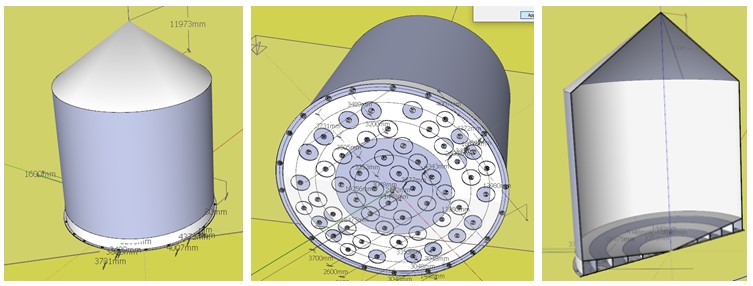

SketchUp 3D model

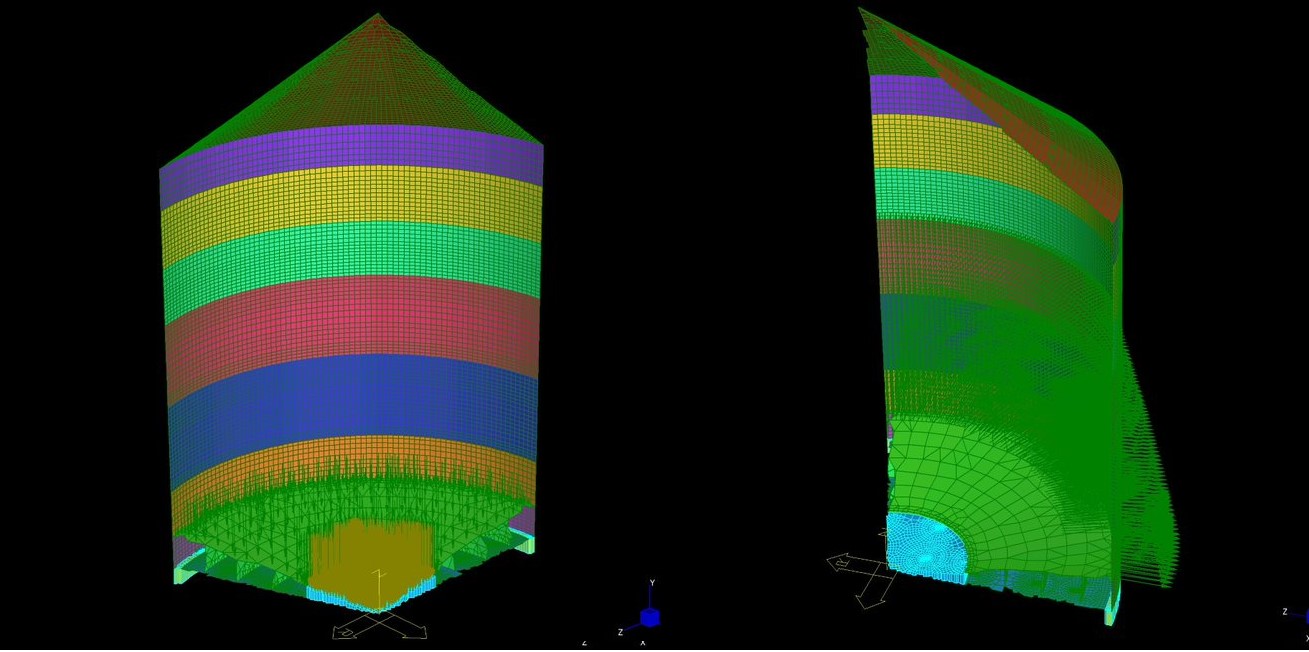

To import into Spacegass as the company I worked for had not purchased Strand7’s automesher module, meaning the model would be meshed in Spacegass but analysed in Strand7.

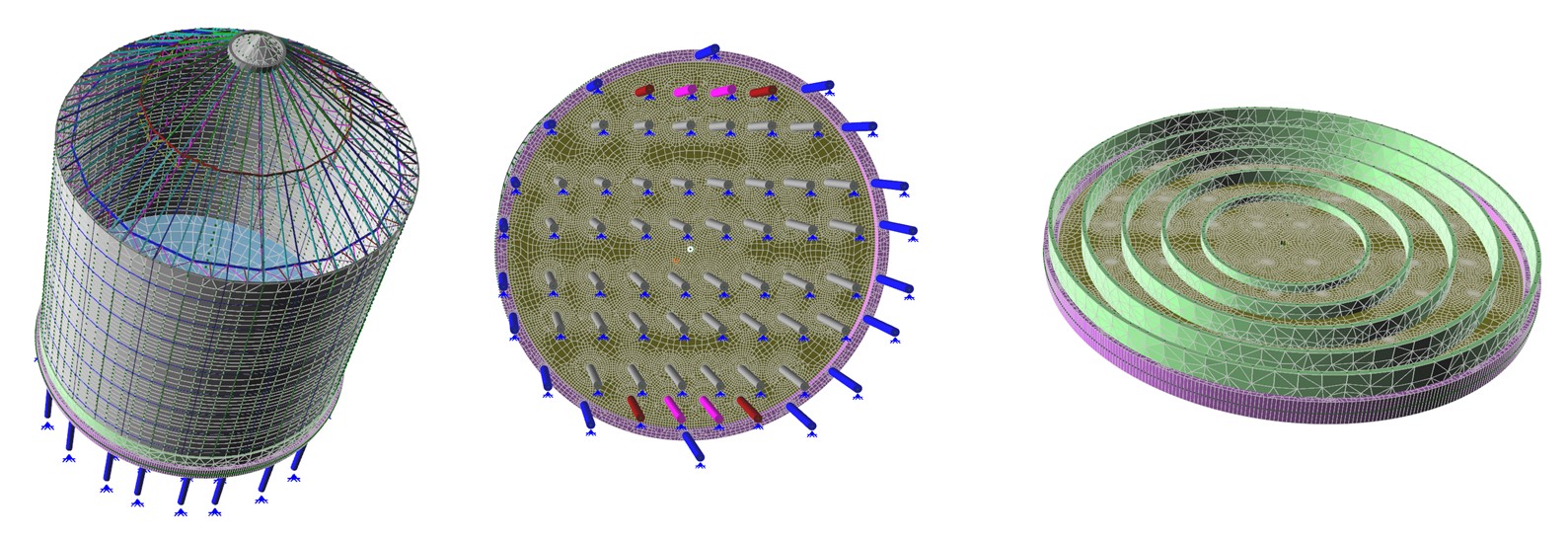

Spacegass Original Model

This model could not be used for analysis due to the inaccuracies of thick plate modelling in Spacegass.

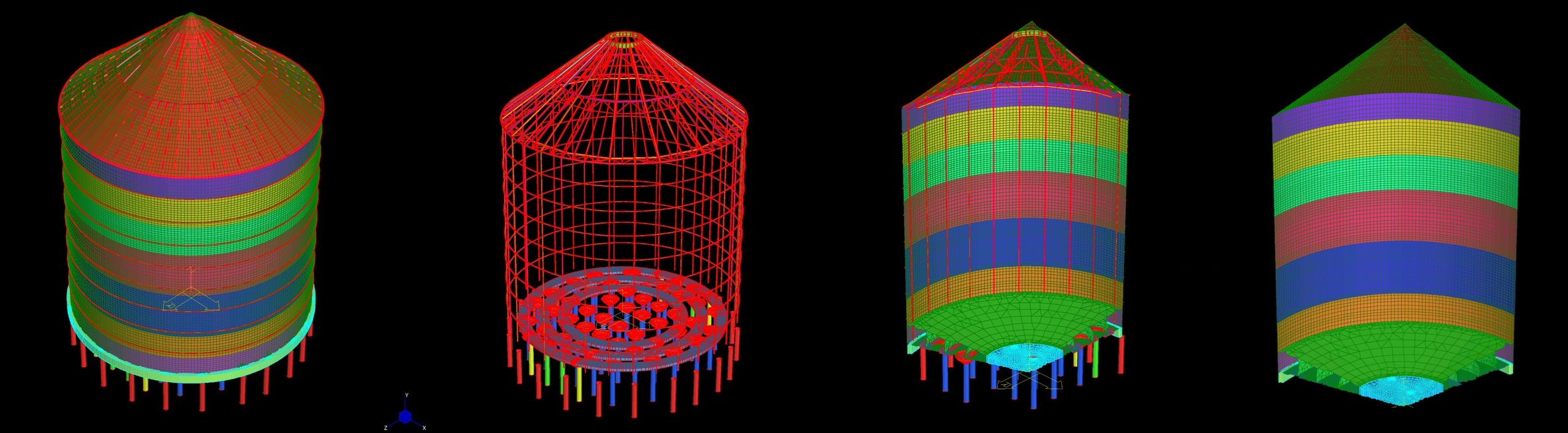

Strand7 Model

The different colour plates refer to the different strake thicknesses as the load increases closer to the base.

Loads were applied directly to the plate/brick elements within Strand7.

Loads were applied directly to the plate/brick elements within Strand7.

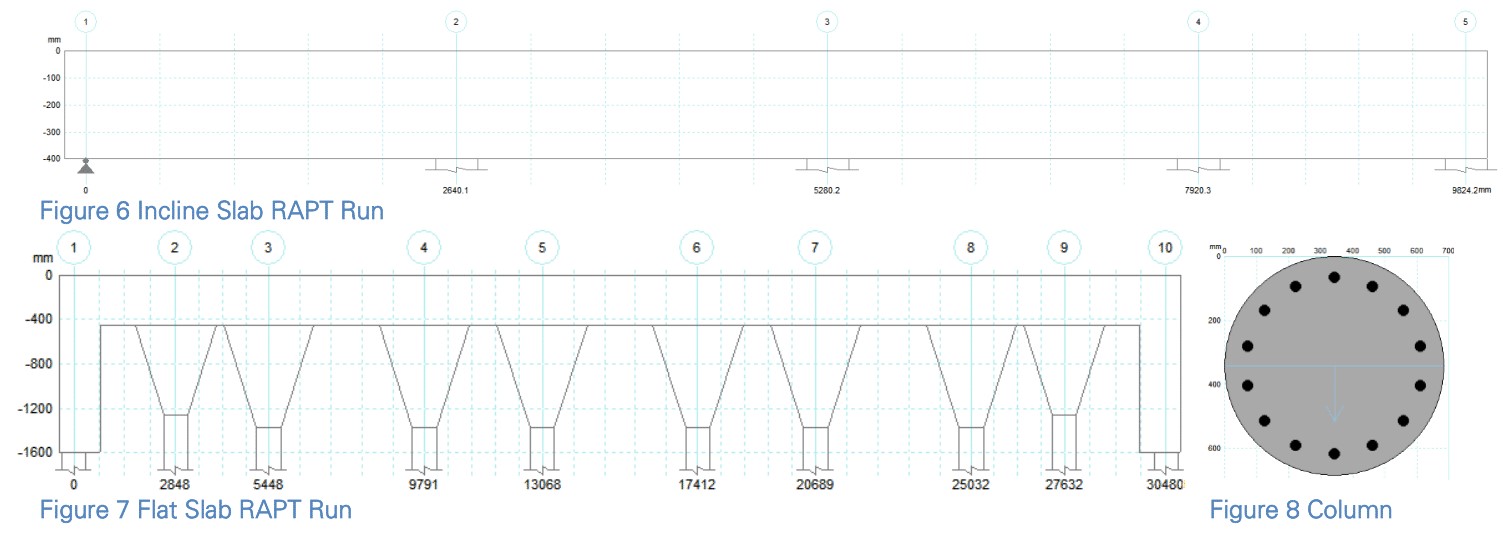

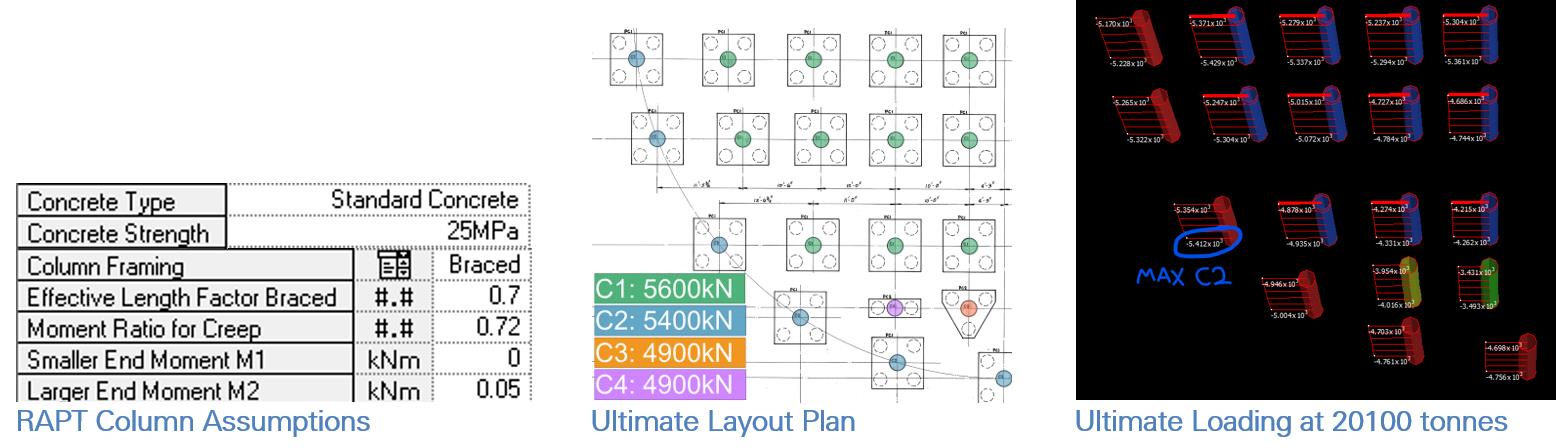

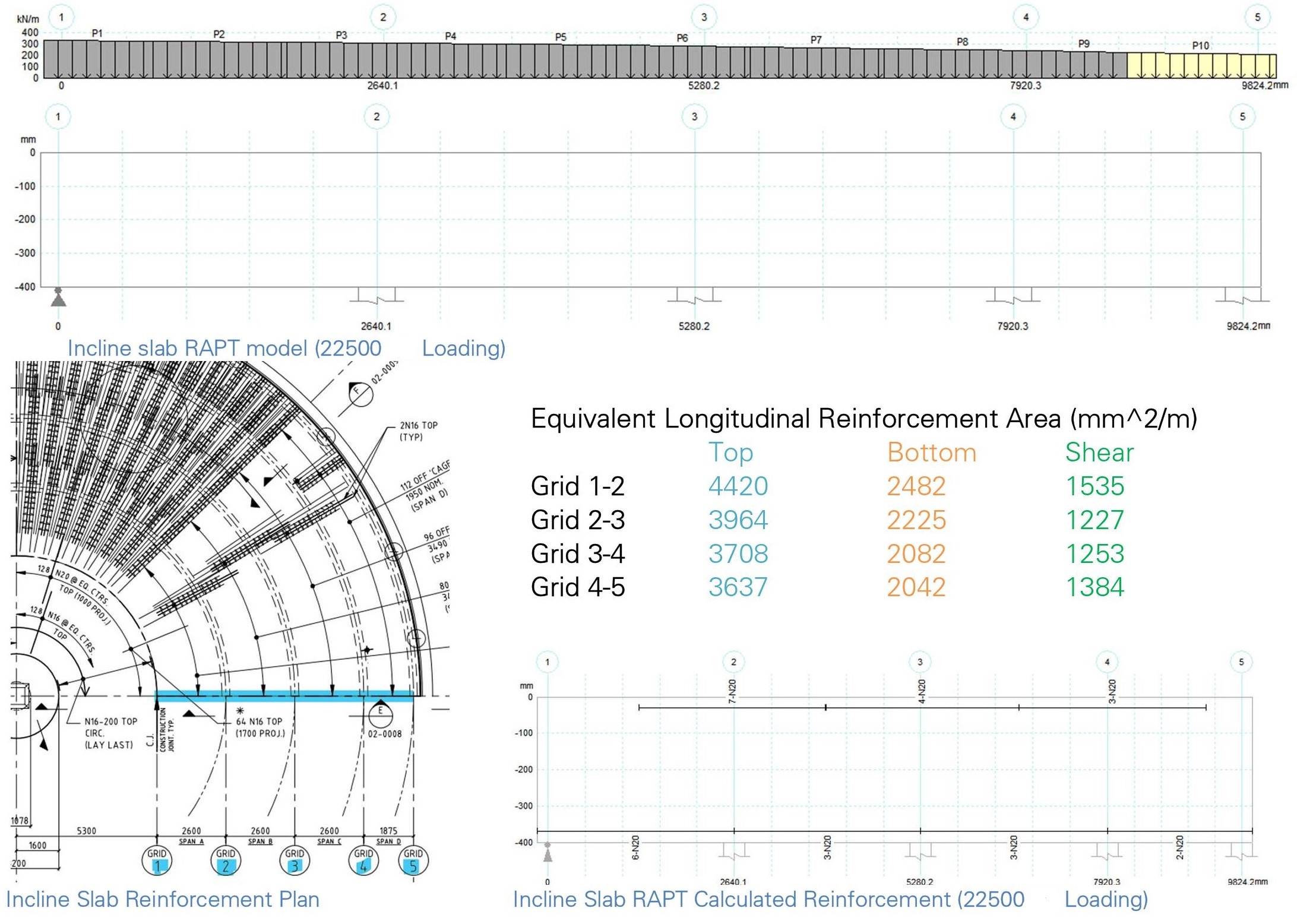

RAPT 2D Models

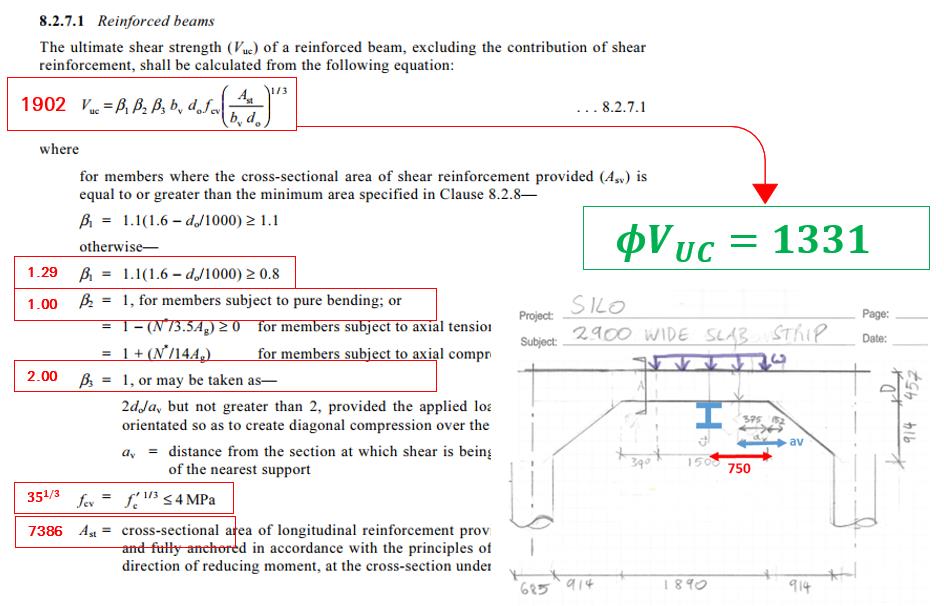

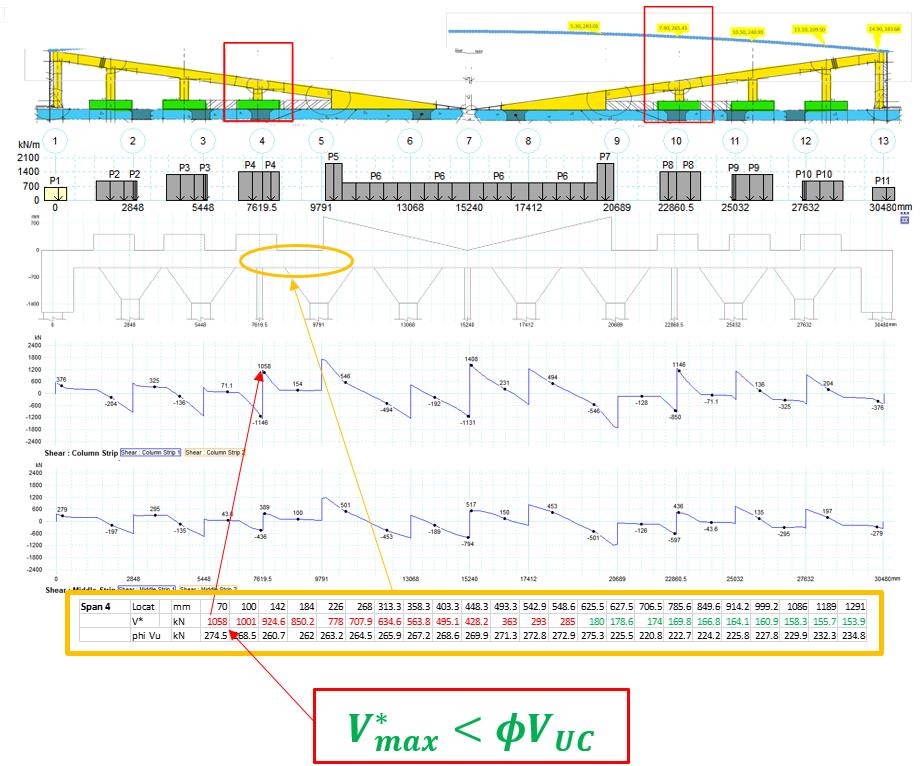

RAPT analyses were undertaken to investigate the capacities of the concrete columns and slabs.

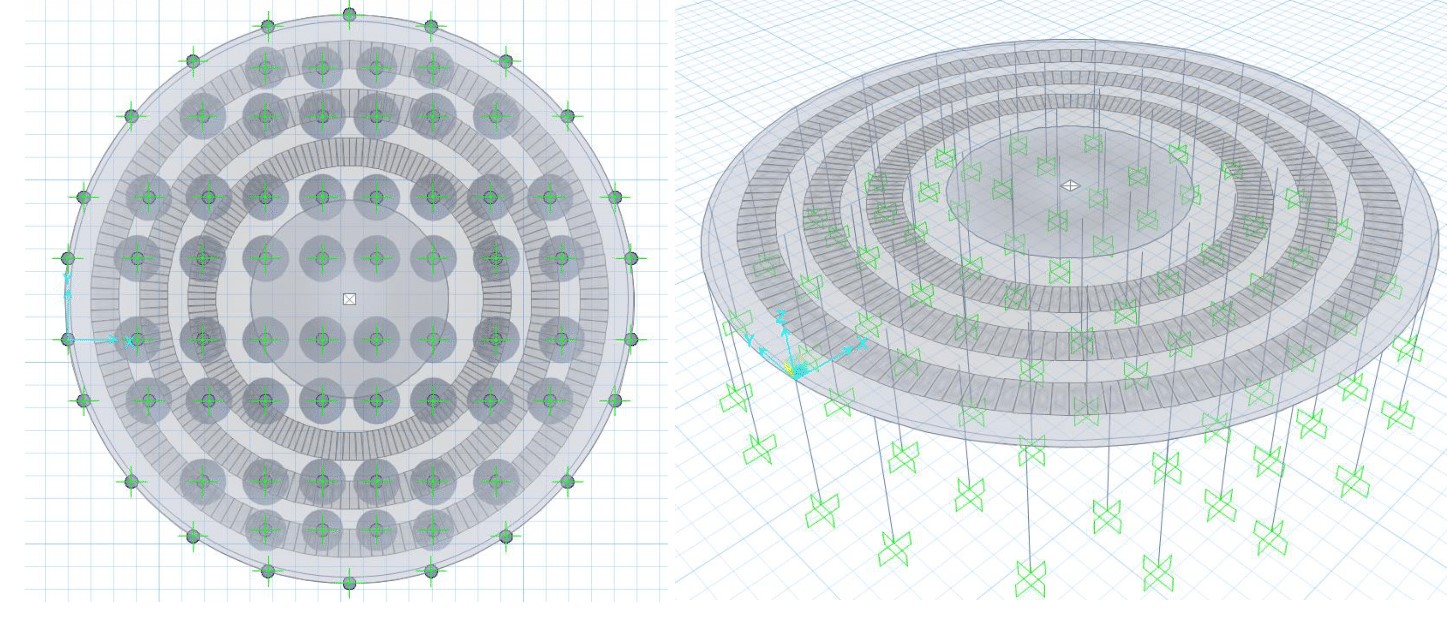

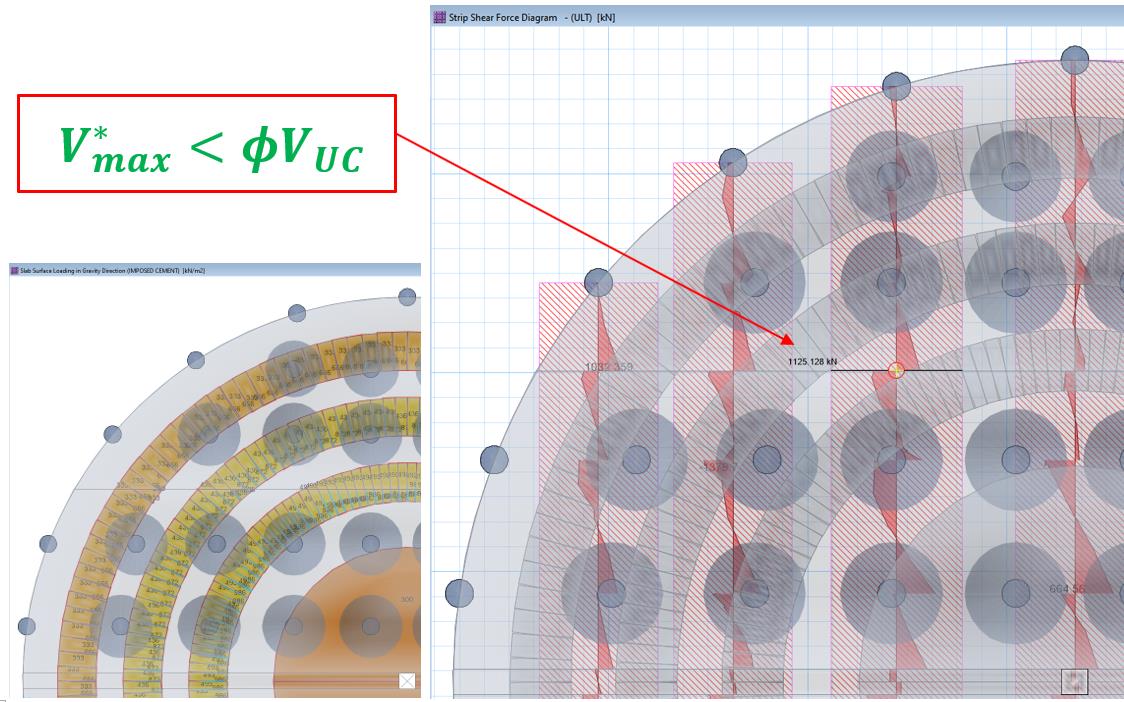

SAFE Model

To further examine the shear strength of the flat slab a SAFE model was created.

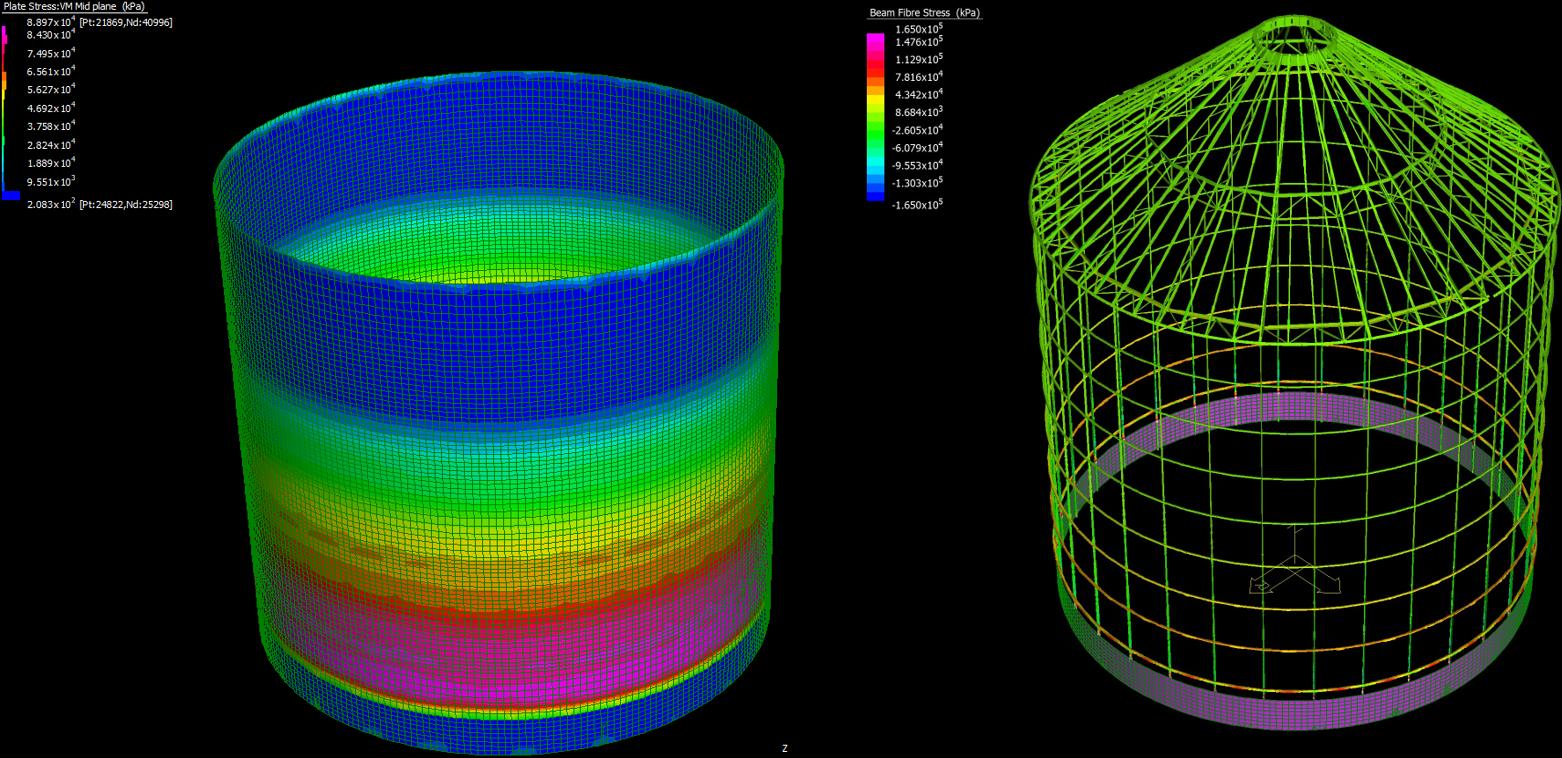

Analyses Results

The extensive modelling allowed for very thorough investigation into the capacities of the comprising elements of the silo and therefore a detailed understanding of the loading capabilities of the structure.

Steel Members/Plates

Given the working steel capacity indicated in the drawings, the structural steel elements limit the structure to more than 23900 Tonnes.

Columns

Although the original 1969 drawings indicated concrete strengths of over 40MPa, compressive strength testing results found one column to only withstand stresses in the order of 26MPa, meaning that the conservative assumption of 25MPa concrete was taken. Even with this conservative assumption the net column loading capacity came out as 20100 Tonnes with a 5% error margin.

Piles

Given a working capacity of 100 Tonnes per pile in the original drawings, the net pile capacity results as 21300 Tonnes with a 5% error margin. An additional caveat is the overloading of the PC3 will be addressed in the new construction, whether that be through soil testing to investigate load distribution or additional supports.

Incline Slab

The incline slab built in 2014 was conservatively constructed and would be able to easily withstand loading above 22500 Tonnes.

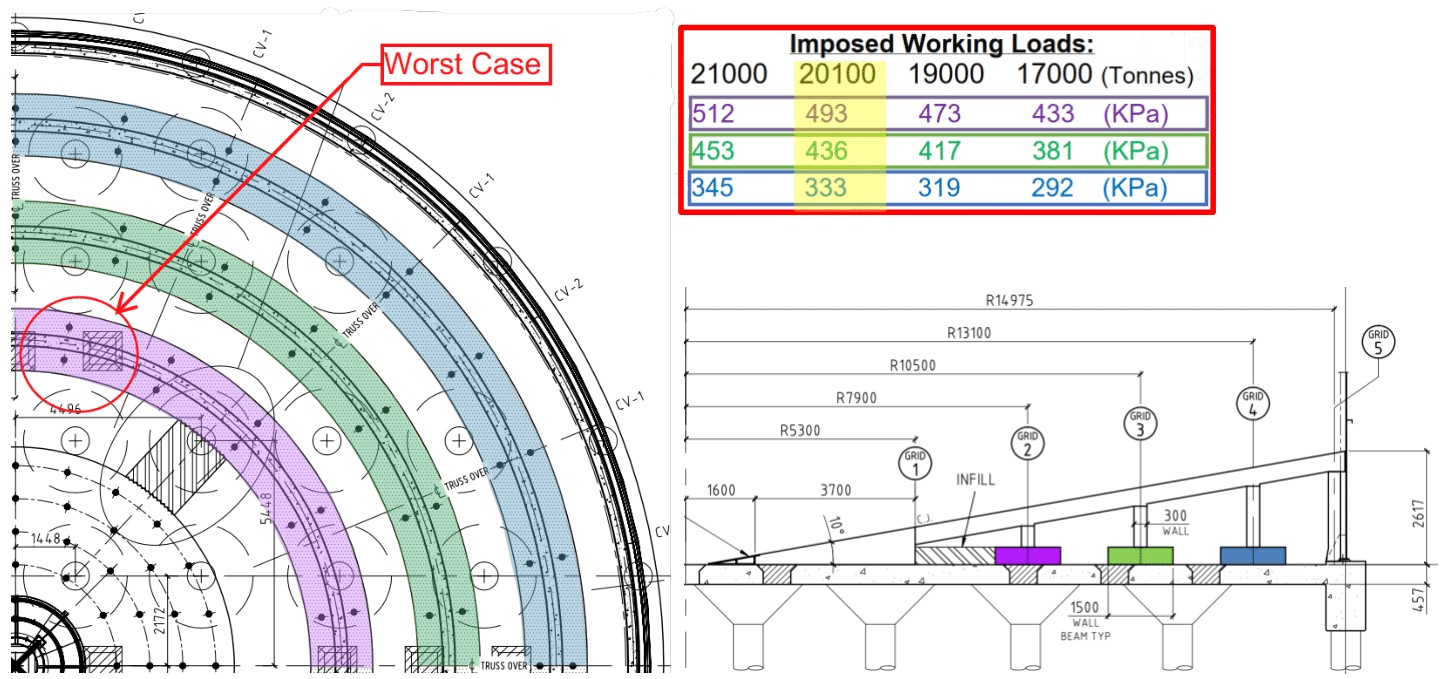

Flat Slab

The longitudinal reinforcement was found to satisfactory under 20100 Tonneshowever analysis of the strip forces in the flat slab revealed shear capacity issues, requiring extensive investigation to assess the upper limits of loads that could be applied. This is why the 2014 capacity investigation limited the structure to a 17500 tonne limit as a wall-bearing band beam is located approximately midspan between 2 supporting columns. As the 1969 construction omitted inclusion of shear steel in the flat slab, the design fails at any loading above 17500 Tonnes.

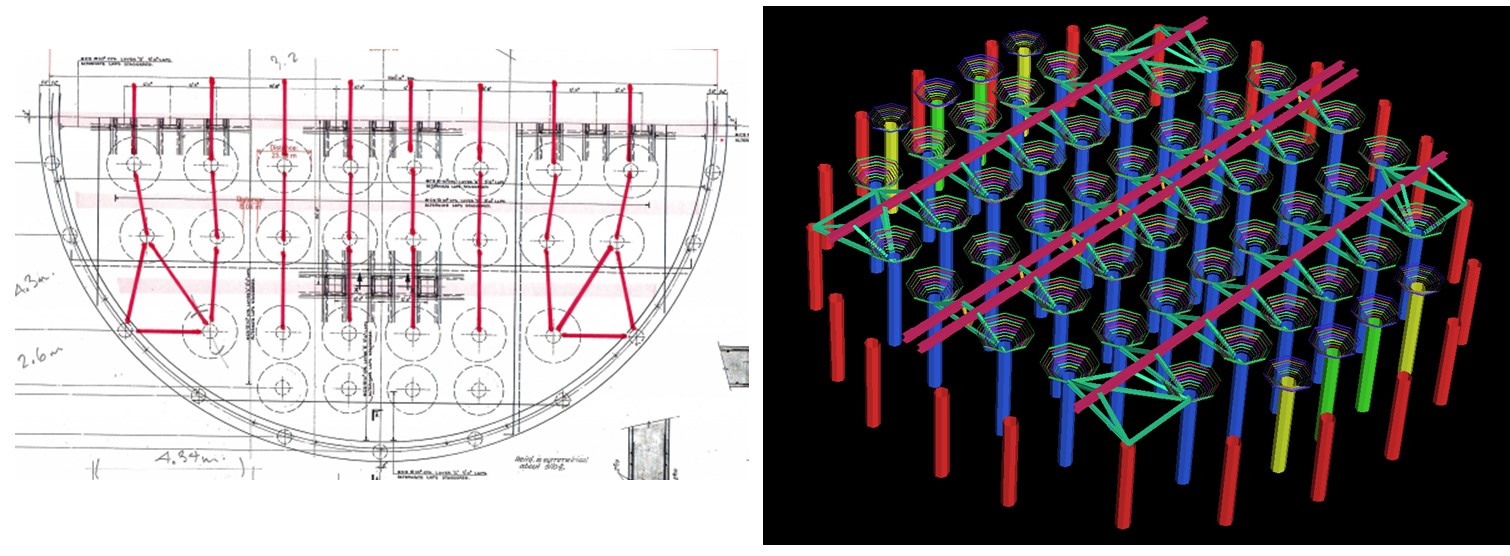

As the client would not be satisfied with a result that provided no capacity increase, the development of a steel structure was designed to sit beneath the critically loaded locations in the base slab.

As the client would not be satisfied with a result that provided no capacity increase, the development of a steel structure was designed to sit beneath the critically loaded locations in the base slab.

Analysis of the structure including the additional steel supports allowed the slab capacity to raise above 20100 Tonnes.

Analysis of the structure including the additional steel supports allowed the slab capacity to raise above 20100 Tonnes.

Comments